The failure is familiar: A round peg never fits into a rectangular space, at least not properly.

The failure is familiar: A round peg never fits into a rectangular space, at least not properly.

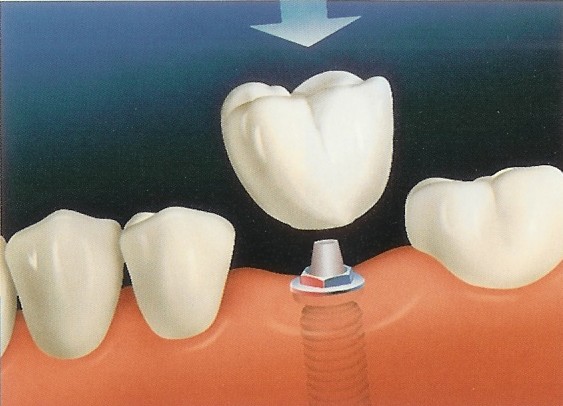

That’s the problem with dental implants when used to replace molars.

The round head of the screw used to hold the top of the artificial tooth creates two crevasses on both sides of the implant when used in the back of the mouth.

The gaps fill with food in places that are nearly impossible to clean with dental floss or without a special brush because the gum tissue sits tightly around the implant, hiding the gaps.

The trapped food accumulates.

That creates a large amount of bacteria.

The bacteria is believed to cause or contribute to several illnesses throughout the body and also gum and bone infection.

“The bacteria forms toxins,” said Dr. James Grant, a Colorado Springs dentist.

“Those toxins can cause problems with your regular health, heart problems and other systemic diseases.”

Grant left Cheyenne Mountain Dental Group, which he helped found in 1990, to create a solution to the problem he terms “BLAD" — the accumulation of breakfast, lunch and dinner underneath dental implants when used to replace molars.

He believes he’s found a solution.

So do others.His company, Grant Dental Technology Corp., has more than 50 shareholders who have contributed nearly $3 million to the company.

Grant Dental is in the third and possibly final stages of raising venture capital.

The company hopes to raise an additional $750,000 by the end of its third fundraising period, which ends Sept. 15.

Grant said regular implants work fine when used to replace the front teeth, or incisors and pre molars, which are held in place by one root.

The problem occurs when implants are used to replace the rear teeth, or molars, he said.Molar replacement surgery makes up more than 60 percent of dental implant surgery, Grant said.Molars are rectangular, multirooted teeth.

Implants, however, are “V” shaped and held in place by a single screw, or one root.

“The final crown looks a lot like a candy apple on stick,” Grant said.“It is basically a round peg in a rectangular space.”

The one-screw fastening method, combined with the V-shaped implant, creates gaps on both sides of the implant between the base of the false tooth and the gum.

Grant has invented an implant called the Proximerge system.

There are several differences between Grant’s system and existing implants, but the greatest is that the base of his implants and the post the artificial tooth attaches to are rectangular.

“So our system is much healthier for the body,” he said, “because it mimics the real tooth.”

Implants are big business: Dental implants were introduced in the 1950s, Grant said, and have since become the preferred method for replacing lost teeth.

Today, dental implant surgery is a $4 billion business worldwide, he said.

It was Grant’s patients who indirectly pushed him to invent his Proximerge system.

On Nov. 29, 2007, a patient told him she decided not to get two artificial teeth because of the irritation and trouble caused by trapped food in her three others.

The next day, Grant had his “epiphany” when doodling during a state-required continuing education course in Denver.

“I thought, if we had an abutment that is anatomically and morphologically similar to a real tooth,” he said, “it will solve the problem.”

Grant took his implant design to Dr. Brad Renehan, who specializes in oral and maxillofacial surgery.

A Springs native, Renehan did his residency at the Mayo Clinic and owns Colorado Surgical Clinic.

After reviewing Grant’s idea, Renehan became an investor in the company.

Grant’s implants are made of titanium, the same metal Renehan has used to fix and form patients’ broken jaws and cheeks.

Renehan said he believes Grant’s implants will be highly successful for several reasons:

•Titanium has a history of integrating into all bones extremely well and not being rejected by the body.

•Grant’s implants use a friction-based spiral locking screw that keeps the post that holds the artificial tooth from coming loose during chewing.

•The implant also uses a newly designed metal tap, the part that holds the screw used to fasten the entire implant system to the jaw bone.

Tests showed Grant’s implants formed a seal that keeps bacteria from accumulating around the implant and possibly causing inflammation and infection, Grant said.

•The square base-plate that fits between the gum and the implant’s crown anatomically mimics a molar, stopping food collection.

Also, the square base plate disperses the pressure exerted across the implant’s surface when a person chews, which is expected to increase the implant’s lifespan.

“We have chewing simulators,” said Duncan Stewart, chief executive officer for Grant Dental Technology Corp., “and we hit the screw 5 million times, and it would not come loose.”